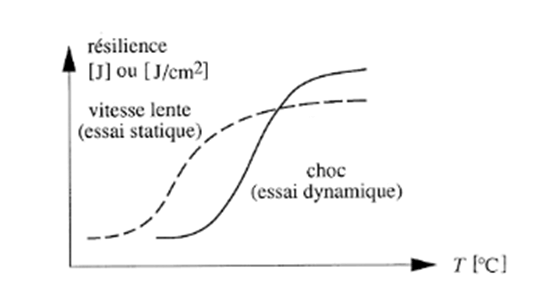

The two curves (Figure 2) are an example of results for a Charpy V-notch test depending on whether the speed of impact is high (impact, dynamic test) or slow (static test). Thus, we can observe that the toughness of the structural steel is a function of temperature and speed of loading. Consequently, the choice of steel grade depends on the specimen’s gauge, the type of structural element, the steel’s strength and resistance, the determining service temperature and thetype of loading applied..

A low temperature, as in northern conditions, makes the steel brittle. A high temperature, as in a fire, reduces the steel’s rigidity and resistance or causes it to dilate.

Fatigue strength

Fatigue is induced in structural elements when they are subject to repeated loads (e.g., frequent hoisting activities, impacts and/or dynamic loads from vibrating machinery, mobile loads on a bridge). Fatigue can cause certain elements to crack, particularly in areas located at right angles to fixation points or welded joints. The principle of assessing fatigue strength is based on the concept of stress difference, the number of load cycles during the structure’s service life and the type of construction detail considered.

For example, when designing a structure to support vibrating machinery (e.g., a crusher for a mining project) that will be built in northern conditions, the number of loading cycles set by the manufacturer must be properly assessed for the equipment’s entire service life. For example, a crusher with a speed of 18 to 60 RPM that operates two hours a day for 25 years will produce 20 to 65 million cycles. When the number of cycles exceeds one million, the structure’s fatigue strength must be verified, while the Charpy test category and the type and grade of steel must be classified based on the CSA G40.21 and CSA S16 standards. Moreover, it is necessary to confirm with suppliers that WT grade steel members are in fact available. This type of steel is not always readily available and may require a longer procurement period.

Other uses

Finally, WT steel is used on bridges for members that are subject to bending or tensile loads. This means that the members undergo repeated impacts throughout their service life—consider the impact you feel when a vehicle drives over the expansion joints of a bridge deck.

If you have any questions about what type of construction steel to use or are facing challenges in terms of planning construction projects in the winter months, our experts from the Structural team can help.