When designing separators to remove hydrocarbons from the aqueous phase the ultimate goal is to reduce hydrocarbon entrainment down to levels that will ensure:

- Successful operation of downstream equipment

- Environmental compliance for disposal of effluent water

As environmental regulations are becoming more stringent, this is driving the need to improve current design methods (i.e., API 421) for hydrocarbon/aqueous phase gravity separation, to ensure discharge limits are not exceeded. The goal is to avoid production curtailment over the production life of the operating facility by ensuring environmentally compliant water discharge.

Effluent Water Targets

Current offshore projects are targeting for 29 mg/l Oil and Grease (O&G) as measured per EPA Method 1664A. The O&G test method determines the hexane soluble components in the effluent water and thus measures:

- Dispersed (free) oil

- Dissolved oil

- Grease (if present)

With future limits likely to be lower, this requires very aggressive removal and well-designed equipment. The margin for design error is therefore reduced and prompts the need for better (i.e., more accurate) design techniques than API 421.

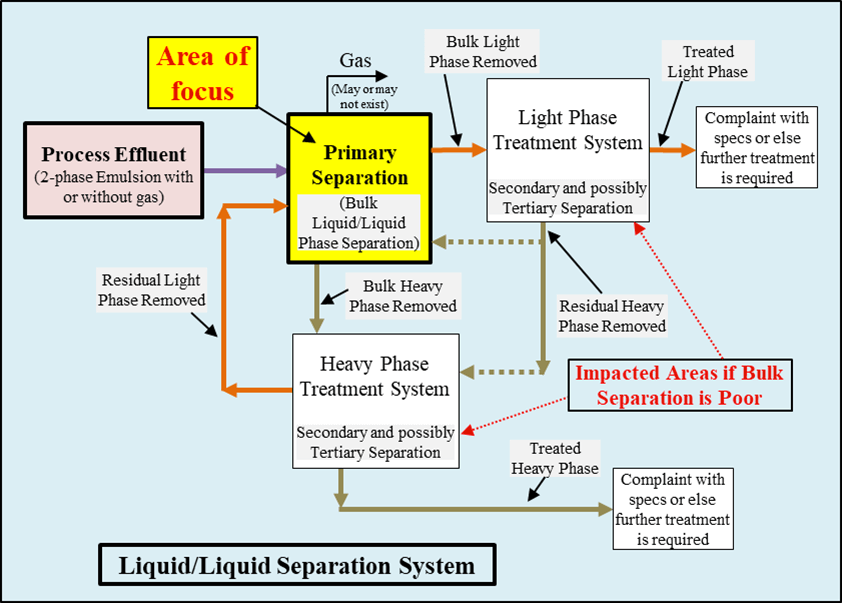

Problem Statement

It is not possible to independently specify a dispersed phase droplet size removal efficiency and a target hydrocarbon entrainment level. Since one parameter is dependent on the other there is only one degree of freedom and not two. The fundamental correlating factor that ties these two parameters together (assuming no coalescence) is the droplet size distribution (DSD) of the dispersed phase droplets generated by the process equipment. It is thus necessary to predict/measure DSD.

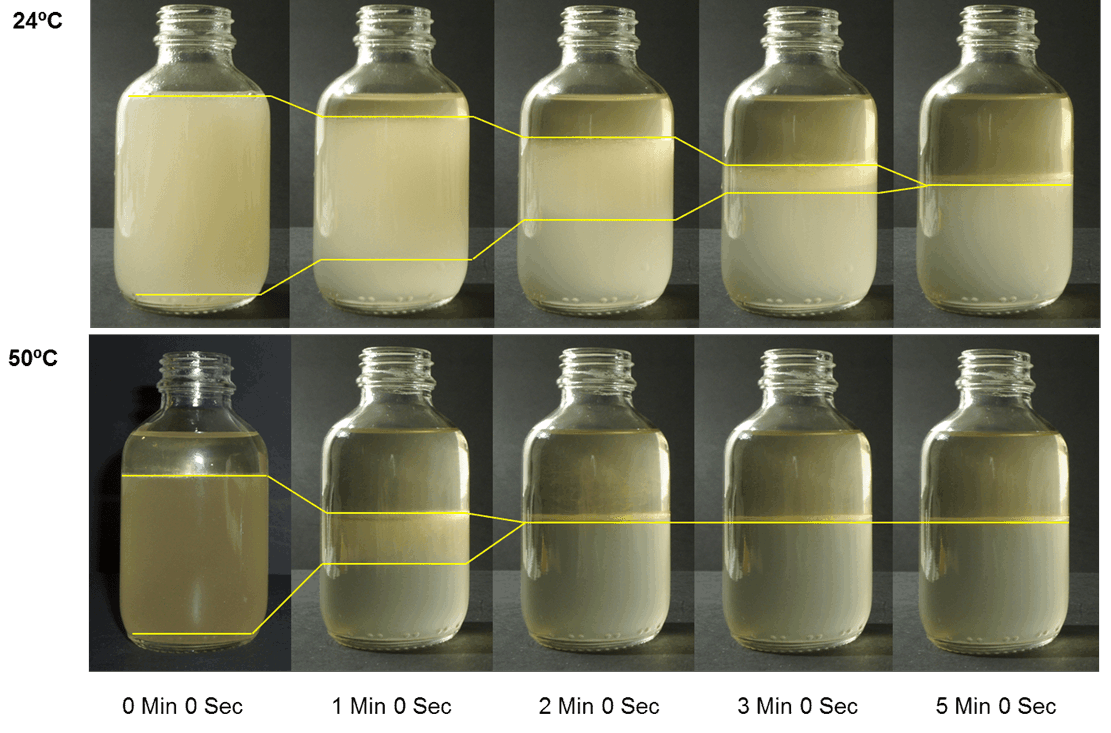

Settling velocity is a function of droplet size and since droplets can coalesce this impact on settling needs to be addressed. Fractional interface coalescence efficiency (fICE), which is the probability of coalescence when two droplets collide with each other, also needs to be determined via experimental measurement.

When modelling how settling takes place (for gravity-based separators) DSD and fICE inputs are both required and hindered settling needs to be considered to properly determine the residence time needed to meet the target removal efficiency.

API 421 vs Enhanced Design Procedure